Test your product with full traceability of process and test performance.

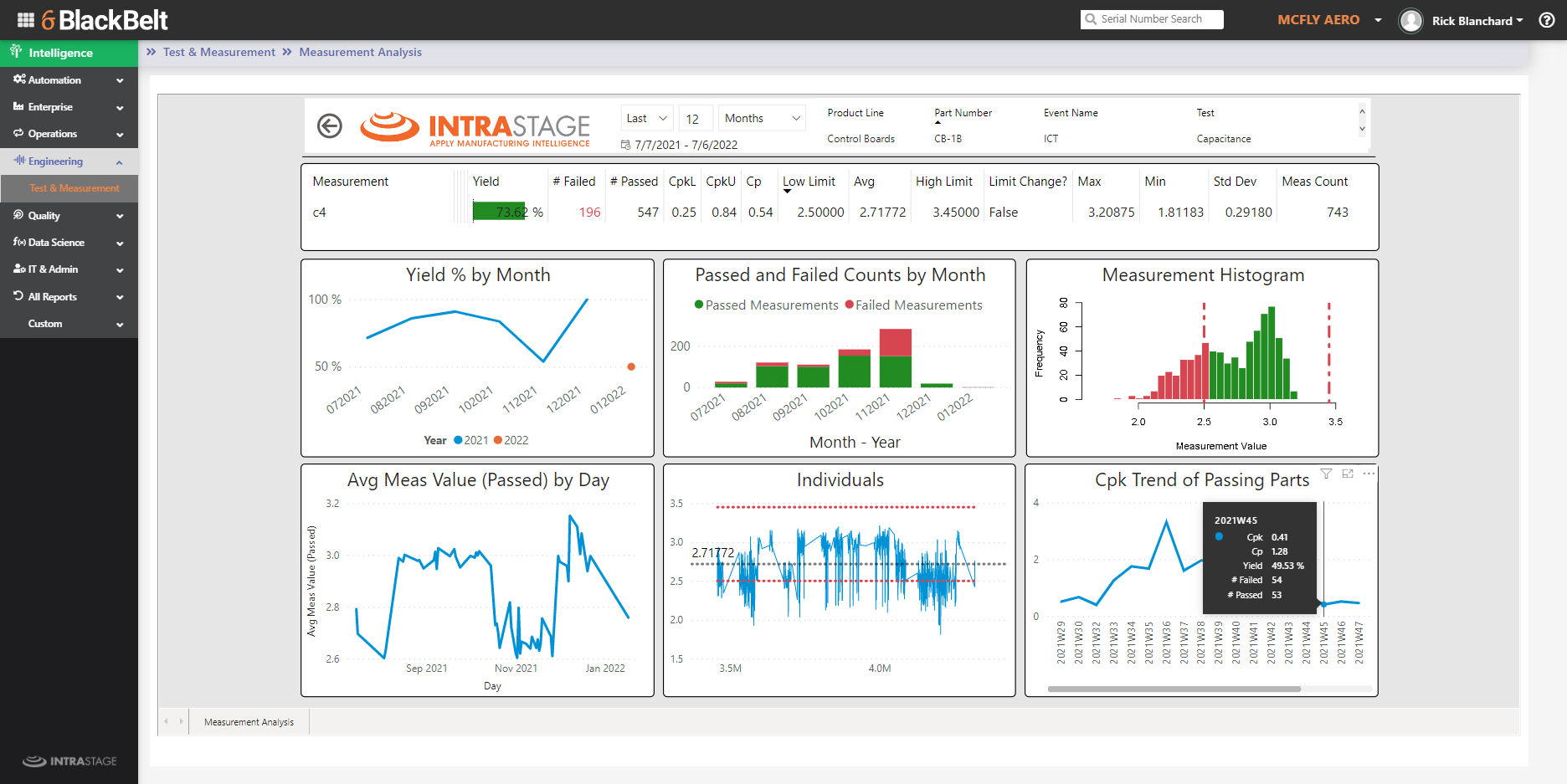

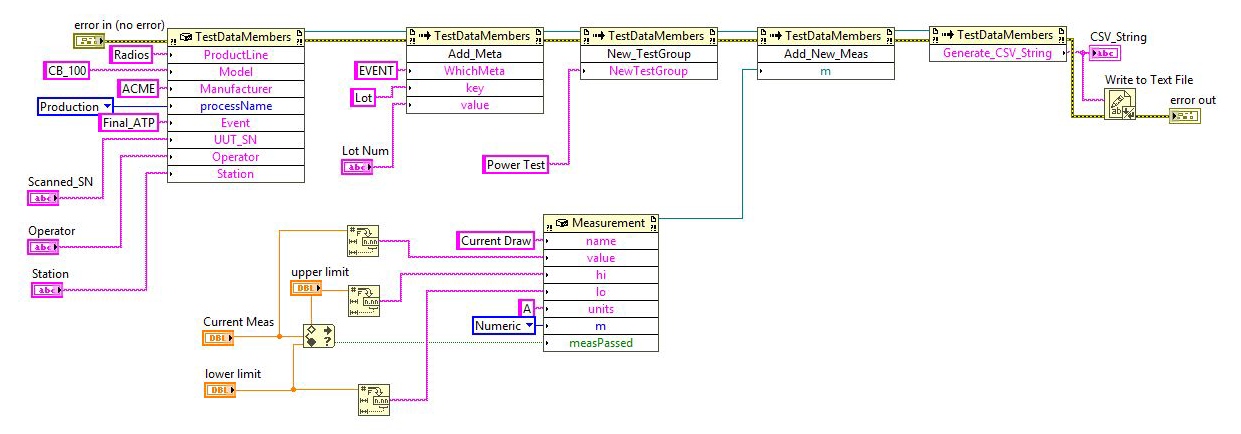

Automatically capture, monitor and analyze test data in real-time from any format

• Web-access to all tester records and analytics

• UUT History/Event Report

• Raw data support, including waveforms

• Complete Serial Number History Report

• Characterize and Correlate

• Statistical Process Control (SPC)

• Failure Paretos

• Station Performance and optimization

• Test Process Performance

• First-Pass, Last-Pass, Throughput Yield

• Retest/Rework

• Drilldown from Yield or SPC to unit performance

• Web-based graphs and charts

• Traceability

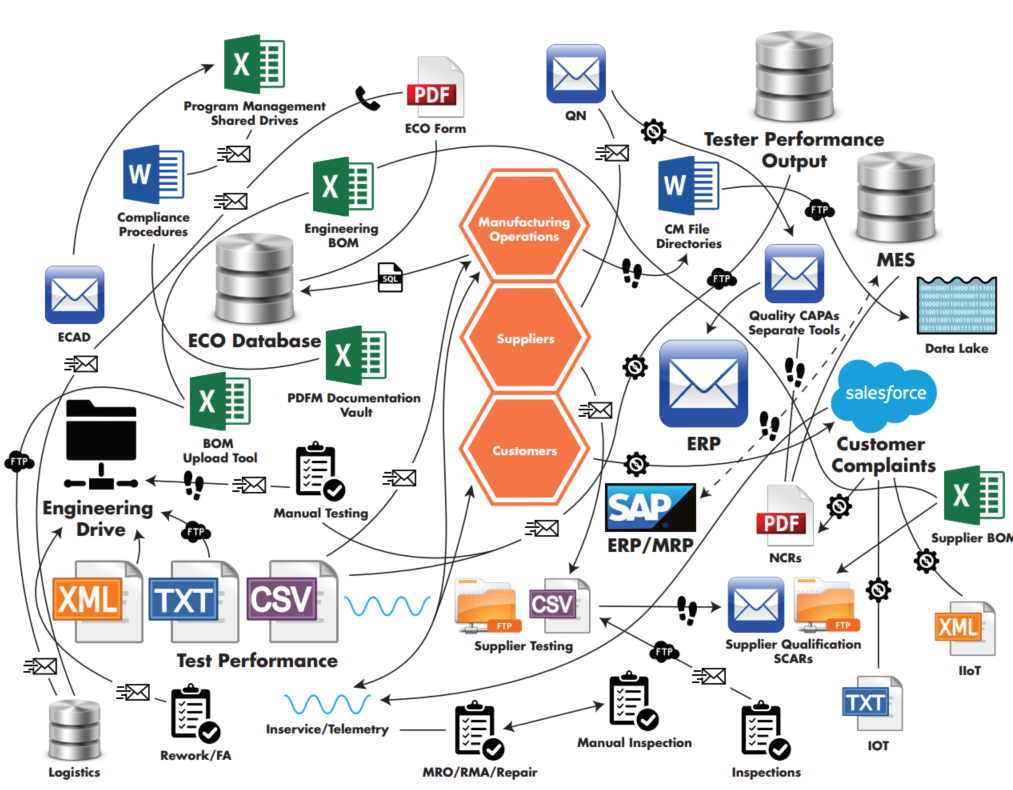

Building the Digital Thread for Electronics Manufacturer requires the ability to seamlessly incorporate new and upcoming sources of manufacturing data, enterprise attributes, and other silo’d data sources.

What to consider when implementing a new test format

• Extensibility

• Compatibility

• Future Proof

Raw Data support

• Customized Formats

• Binary, text, images, PDF, other

• (PDF Download): Application of ATML Test Results and IntraStage to facilitate Intelligent Data Analysis

• (PDF download) How To Use Test Data to Better Manage ATEs

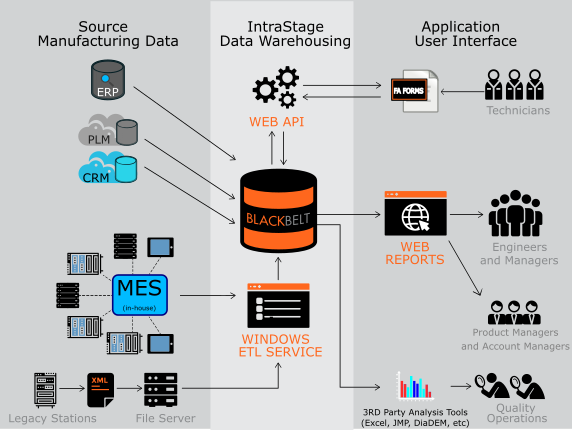

Success with a Manufacturing Intelligence platform requires a firm understanding of a company’s current manufacturing environment, digital readiness, and roadmap to the factory of the future.

• Customization and Integration use case

• Integration of manufacturing parametrics with existing PLM, ERP, and MES

• ETL process for new datasets

• Features of a complex electronics data warehouse

• (PDF Download): Digitize Your Paper-Based Test Data to Generate New Insights

ENGINEERING TOPICS

Manufacturing Intelligence means having the off-the-shelf analytics and documentation to deploy and support advanced test engineering features.

• Gage RnR on-demand

• Realtime SPC and WECO

• Hidden Factory

• Other DB integration

• Enterprise integration

• Emerging standard and best practices

• Workflows

• Spec phase/requirements

• Subscriptions

• The Power of Attributes and Metadata

• Applying Machine Learning and A.I.

• Strategy for Very Large Datasets

Yield and Pareto drilldowns

Learn how General Atomics digitized multiple data silos to ID issues that affected product quality.

SPC insight

Converting ATE data and digitizing paper forms to identify and resolve manufacturing problems quickly.

CASE STUDY

Turning Data Into Action

Learn how Medtronic integrated BlackBelt to gain a full picture of their KPIs.

Real-time visibility

Full system monitoring product quality and process efficiency.

CASE STUDY

Lower Costs, Faster Production Time

Analyzing data from across the product lifecycle

WiP and Cycle Times

Intelligence from supplier subcomonents, CM Lower-Level Assemblies, and Higher-Level Assemblies.

CASE STUDY

See how BlackBelt can deliver full traceability of test and performance. Start your FREE Trial.