Performance for the Modern Enterprise

IntraStage BlackBelt Fusion is the premier manufacturing intelligence platform for complex electronics manufacturers who need full product lifecycle intelligence.

“Transforming our processes to optimize proactive quality management has saved our organization hundreds of man-hours per year and improved our Rolled Throughput Yield. BlackBelt software has changed the engineering workflow to a proactive model by addressing issues as they arise with instant notifications, alerts, and complete visibility.”

Senior Test Engineer, Medtronic.

Why Choose IntraStage BlackBelt Fusion?

- Rapid root-cause and identification

- Improved engineering cycle time

- Higher manufacturing yield and throughput

- Improved product reliability and zero defects

- Instant visibility into key manufacturing issues

- Increased Engineering Efficiency

- KPIs for Product Lifecycle Intelligence

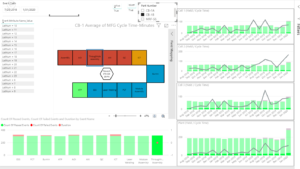

- Interactive Analytics

In-memory performance means that your analytics load lightning fast. With multivariate analysis and click-through deep-dive and drill through analytics, your users can quickly pivot on their selected data and understand factors, root-cause, and correlations like never before.

In-memory performance means that your analytics load lightning fast. With multivariate analysis and click-through deep-dive and drill through analytics, your users can quickly pivot on their selected data and understand factors, root-cause, and correlations like never before.

- Best-in-class prebuilt analytics with in-memory performance

- Automated insights with alerting and subscriptions

- Open architecture for 3rd party analytics (Excel, PowerBI, etc)

Case Studies

Yield and Pareto drilldowns

Learn how General Atomics digitized multiple data silos to ID issues that affected product quality.

SPC insight

Converting ATE data and digitizing paper forms to identify and resolve manufacturing problems quickly.

CASE STUDY

Turning Data Into Action

Learn how Medtronic integrated BlackBelt to gain a full picture of their KPIs.

Real-time visibility

Full system monitoring product quality and process efficiency.

CASE STUDY

Lower Costs, Faster Production Time

Analyzing data from across the product lifecycle

WiP and Cycle Times

Intelligence from supplier subcomonents, CM Lower-Level Assemblies, and Higher-Level Assemblies.

CASE STUDY