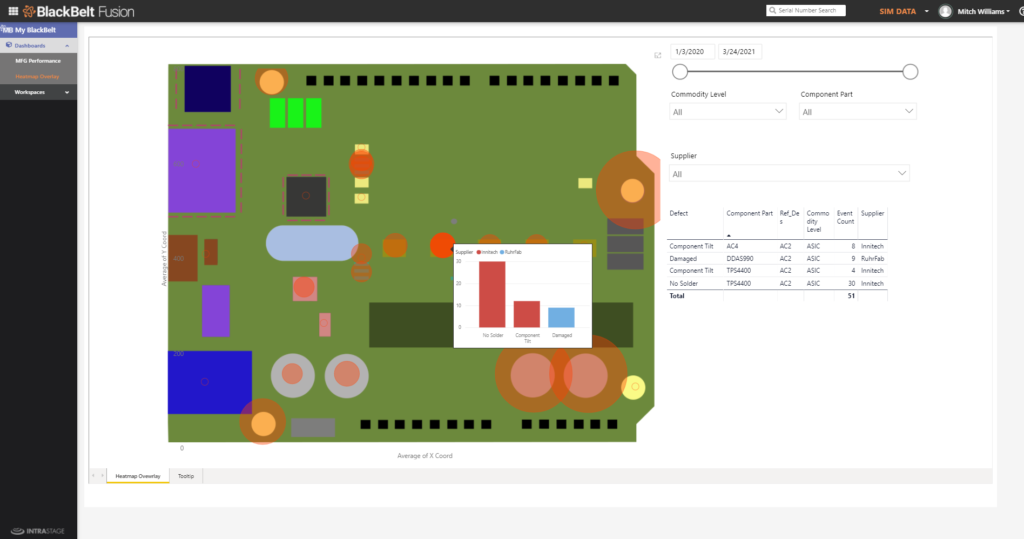

Heatmap Overlay

Digital Twin Use Case: Rework Insight

Having high-level metrics is good; having high level metrics integrated with workflows that leverage the underlying details that drive and provide insight into the metrics is better. A board overlay is a prime example of having multiple sources of data inform a workflow that outputs in better quality and processes.

Challenge:

- Linking NPI/Design, Rework, and Supplier Quality information

- Real-time insight into failure modes and reasons

- Hidden Factory insight

- Accelerate Rework/Repair processes

- Identify emerging supplier quality issues

Solution:

- Merging as-designed and as-built information

- Automated capture from Repair/Rework processes

- Manual data capture using digital forms

- Off-the-shelf data warehouse

- Data model designed for parametric analysis

- SSAS for rapid data analyzation

Benefits

- Faster repair and rework by leveraging historical data

- Quickly identify failing components

- Better and faster design processes

- Rapid evaluation of failure by design or by process

- Better supplier management

- Real-time insight into failures by supplier

- Augmented reality-ready workflows

With detailed information like this, organizations can quickly triage problems by identifying the underlying source of those problems, whether it be from a supplier, a method, design, or a process in need of improvement.

Changing any of these parameters in a modern electronics manufacturing environment requires proof. Proof means data that is linked, normalized, reportable, and validated: the digital twin.

The values of these different digital twin categories are difficult to unlock without breaking them out of their silos and linking them together into a cohesive whole. By deploying a manufacturing intelligence system that provides a single source of truth of the digital twin across all these categories, electronics manufacturers can deploy uses cases like the ones below to drive better product quality and better efficiency.

A complete digital twin drives better manufacturing performance, quality, and outcomes. With IntraStage BlackBelt Fusion being the most complete version of the digital twin anywhere by making data analyzable and usable, contact us for a demo on how we can use our demo data or your actual manufacturing data to show you the power of the digital twin.

PPM and DPMO

Prevent Customer Escapes, Improve Efficiency

OEE and Cycle Time

Improve Manufacturing Velocity and Productivity

As-Built, As-Maintained, As-Is

Full Traceability and Genealogy

Get the FREE TRIAL