Get the FREE TRIAL

- Secret/Classified/ITAR requirements

- Cloud deployment needs

- Hybrid platform deployments with global scalability

- Multi-Server/airgapped/multi-location requirements

- Highest value streams and priorities

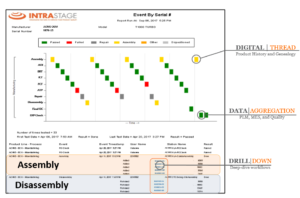

Speed your team’s ability to root-cause workflows and analysis across your enterprise systems. Fuse your product performance data with your enterprise data attributes from PLM, ERP, and MES to provide click-through drill-down workflows from a single-source of truth.

On-Demand Characterization Across Your Enterprise

- Verify process stability with SPC Analytics (including Cp and Cpk, X-BarR, Box and Whiskers charts, and WECO)

- Drill-down genealogy to your supplier base (Paretos at the Product Line, Part/Model, Process, Event, Test and Measurement level)

- Yield insight and drill-down at every level of production

Rapid Root-Cause Issues

- Full associated genealogy of your product with performance history of every component and lower-level assembly

- Aggregated performance metrics across your enterprise provide yield insight (with characterization and drill-down) at every level of manufacturing

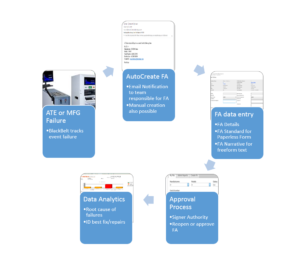

Reach beyond compliance. Maximize service life with failure analysis workflows and integrated analytics.

Workflow

- Capture all attributes of diagnostics and root cause with tailored forms with rapid time to value

- Integrated, flexible approvals and signing authority

- Speed your MRO process with diagnostic reporting

Failure Analysis Analytics

- Reliability analytics in a single solution (MTTF, FIT Rates, etc)

- Track unit life-cycle performance

- Reduce service cycles with normalization and modeling of data for clustering and advanced analytics

- CONTACT US

The voice of your customer is in your returns. Are you listening?

Capture and analyze customer return data to better understand where processes and products need to evolve to improve product quality.

Product Quality Insight

- Quickly understand why your customers are returning your products, and know how to resolve the issue: Characterize RMAs by Defect/Model/Return Rate/Customer/Supplier/Contract Manufacturer

- Use enterprise-level analytics that drive better product quality: use drill-down enterprise analytics like Mean Time Between Control Failures (MTBCF) Mean Time Between Failures (MTBF) and Mean Time To Repair/Return (MTTR)

RMA Process Quality Control

- Fully track RMAs from genesis to completion, and have the confidence that your RMA processes are compliant and cohesive: integrate with CRM and ERP using the IntraStage API

- Gain insight into efficiency and productivity metrics like Warranty Analytics and Cost of Repair/Labor Analytics

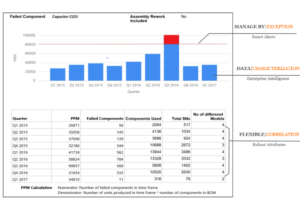

Manage By Exception with smart alerts on your key performance indicators.

Associate and Predict

- Normalize historical data from across your enterprise to learn the characteristics of failure.

- Manage By Exception to give your team the alerts they need to stay on top of and investigate trending issues

- Normalize and relate your product data to enable machine learning and clustering

- Training the system to understand how to set thresholds to uncover trends before they become problems

- Manage By Exception with customizable, smart alerts

Automate and Prescribe

- Maximize product quality by applying correlated characteristics of performance and design failures to prescribe resolutions

- Maximize process throughput by automated identification of bottlenecks

Rolls-Royce (formerly Controls and Data Services)

safety critical controls and asset intelligence solutions for industrial power, marine, civil, and military aerospace

Challenge

- Highly complex products with tight safety and reliability metrics

Need to analyze production data to quickly identify issues affecting yield and performance - Data aggregation from AOI,AXI,ICT,FCT, ESS, Failures, Rework and ATP performance test.

- Apply Statistical Process Control (SPC) across a wide number of process variables such as CpK.

Solution

- Implementation of IntraStage BlackBelt Manufacturing for automated Data Management.

- Robust data model enabling OLAP Cube Analytics

- Out of the Box Quality Reports

- Open system enabling custom report development and Enterprise Integration

Benefits

- £500,000/(year over year) savings since 2005

- Predictive Analysis on Key Process Variables using SPC.

- Reduced time for defect analysis from two weeks down to seconds

- Dramatically improved throughput yield and cycle time

Embrace the Factory of the Future With IntraStage BlackBelt

Depth of insight and richness of visibility is at the center-point of Factory 4.0. Drive the digital transformation of your quality, performance and enterprise data into the Factory of the Future. with our industry-leading software built on utilizing the performance and test data you already collect to unlock new insights.. See how linking together Enterprise data like MES, ERP, PLM, and CRM can enrich your visibility into product performance, throughput, and quality, with outputs like:

- Increase Rolled Throughput Yield

- Reduce Time to Investigate Issues by 90%

- Accelerate Time to Market by 40%

- Traceability of final assembled units and sub-components throughout product lifecycle

- Associate data into a Single Source of the Truth

- Manage by Exception with intelligent alerts and notifications

- Empower a Collaborative Approach to Quality in the most difficult technical arena

- Understand how IntraStage will not disrupt your existing processes

Rich Analytics

- Yield

- Retest

- Repair

- Rework

- Returns

- SPC

Workflows

- Failure Analysis

- RMA/Returns

- Repairs

- MRO

- Depot

- Drilldowns

- Rootcause

Compatabilities

- TestStand

- LabVIEW

- KeySight

- GenRAD

- Teradyne

- …many more

Data Sources

- SQL

- ATML

- XML

- CSV

- XLS

- CSV

- TXT

- …many more

Lifecycle Data

- Design

- NPI

- Supplier

- Manufacturing

- Assembly

- Test

- In-service

- Repair