Last Chance to Register for our Microsoft Webinar: Optimize Remote Manufacturing Data: Ensure Process Quality with Digital Twin

Last Chance to Register:

Optimize Remote Manufacturing Data:

Ensure Process Quality with Complete Digital Twin

Register and join us in our Microsoft webinar on October 13th at 10 AM Pacific time. We’ll talk about how in today’s digitized manufacturing world, complex electronics manufacturers need to improve productivity, yield, and throughput by leveraging the digital twin.

We’ll share some use cases and examples of how our customers are achieving their enterprise goals by digitizing, warehousing, and analyzing their data in near real-time. We’ll also be joined by a customer who will share how his organization has used BlackBelt to help transform their remote manufacturing and increase their manufacturing efficiency and product quality.

Register by clicking on the Microsoft link and join us to learn how you can transform your organization for the new normal.

Sharing the Data: Why Contract Manufacturers Feel the Pain

Sharing the Data: Why Contract Manufacturers Feel the Pain It’s a daunting challenge for a Contract Manufacturer (CM) to aggregate and report data to a customer. Typically, they have to use manual labor to take the appropriate data, parse it into their system, and manually crunch the data (using Excel sheets or similar

Transparency is Coming: Are You prepared to give full transparency to your OEMs today?

Transparency is Coming: Are You prepared to give full transparency to your OEMs today? As Original Equipment Manufacturers (OEMs) seek closer ties with their Contract Manufacturers (CMs) in order to more fully control their supply chain during this uncertain economic climate, expectations on those contract manufacturers are evolving. OEMs are purchasing or implementing solutions that

Contract Manufacturing Tools and Practices: What’s Your Take?

Contract Manufacturing Tools and Practices: What’s Your Take? The last couple of weeks we’ve been blogging about the issues and challenges OEMs face when dealing with contract manufacturing. One particular problem we hear again and again from OEMs is how difficult and time-consuming it is to obtain a true record of test data from contract

Webinar: Optimize Remote Manufacturing Data: Ensure Process Quality with Digital Twin

Optimize Remote Manufacturing Data:

Ensure Process Quality with Complete Digital Twin

Register and join us in our Microsoft webinar on September 22nd at 10 AM Pacific time. We’ll talk about how in today’s digitized manufacturing world, complex electronics manufacturers need to improve productivity, yield, and throughput by leveraging the digital twin.

We’ll share some use cases and examples of how our customers are achieving their enterprise goals by digitizing, warehousing, and analyzing their data in near real-time. We’ll also be joined by a customer who will share how his organization has used BlackBelt to help transform their remote manufacturing and increase their manufacturing efficiency and product quality.

Register by clicking on the Microsoft link and join us to learn how you can transform your organization for the new normal.

Sharing the Data: Why Contract Manufacturers Feel the Pain

Sharing the Data: Why Contract Manufacturers Feel the Pain It’s a daunting challenge for a Contract Manufacturer (CM) to aggregate and report data to a customer. Typically, they have to use manual labor to take the appropriate data, parse it into their system, and manually crunch the data (using Excel sheets or similar

Transparency is Coming: Are You prepared to give full transparency to your OEMs today?

Transparency is Coming: Are You prepared to give full transparency to your OEMs today? As Original Equipment Manufacturers (OEMs) seek closer ties with their Contract Manufacturers (CMs) in order to more fully control their supply chain during this uncertain economic climate, expectations on those contract manufacturers are evolving. OEMs are purchasing or implementing solutions that

Contract Manufacturing Tools and Practices: What’s Your Take?

Contract Manufacturing Tools and Practices: What’s Your Take? The last couple of weeks we’ve been blogging about the issues and challenges OEMs face when dealing with contract manufacturing. One particular problem we hear again and again from OEMs is how difficult and time-consuming it is to obtain a true record of test data from contract

BlackBelt Fusion Now Available on Azure Marketplace

BlackBelt Fusion Is Now Available on the Azure Marketplace

With IntraStage BlackBelt Fusion now available for Transact on the Azure marketplace, customers can now streamline their purchasing process for the industry leading Fusion platform.

By being able to use existing corporate Azure consumption goals, purchasing managers can fulfill contractual spend obligations with Microsoft while delivering their operations, design, and process engineering teams a system that provides rich analytic insight into product and process performance. With deployments available in the Azure cloud, customers can accelerate their deployment process and achieve faster time to value. In addition, on-premise customers can bring their own licenses (BYOL) for migration, thereby achieving purchasing and operational streamlining. Customers can now leverage the IntraStage and Microsoft partnership to achieve such advantages as:

- Faster time to deployment and a simplified purchasing cycle and (“Click to Accept” standardized terms)

- Consolidated billing

- Free Test Drive available through Azure

- Private offers exclusively tailored to fit your specific business needs

- Streamlined business processes via pay as you go options with Azure managed consumption

- Flexible deployments methods (full SaaS or deployed in your Azure tenant)

- Align with your their enterprise cloud strategy by contributing to their Azure cloud migration and consumption target

- Integrate department software solution needs at the enterprise solution level.

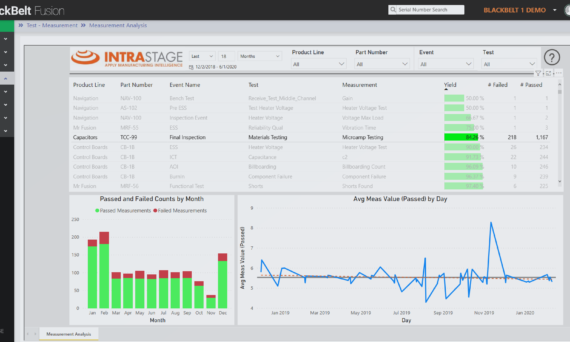

BlackBelt Fusion delivers the complex electronic industry’s first embedded PowerBI manufacturing dashboard for KPI insight and root-cause analysis. With rich insight on electronic manufacturing process and product, from high level KPIs all the way down to root-cause and SPC analysis at the parametric level, Fusion helps customers apply manufacturing intelligence by delivering:

- Interactive analytics with the speed that inspire data-driven culture at every level.

- Embedded – BI for everyone (web-distributed analytics for the full product lifecycle, including supply chain insight)

- Confidence in single source of truth

Contact us to get a demo of our Azure cloud-hosted platform, and see what a representation of the digital twin can do for you.

Security Frameworks and Considerations

ISO 27001 and CMMC Level 3: Security Frameworks and Considerations When IntraStage’s CyberSecurity Council evaluated the different possible frameworks for security, we decided on an ISO-27001 compliance path for the following reasons: Global recognition: The international acceptance of the standard helps us support our customers in the UK and other nations across the globe. Framework

Reshoring Manufacturing: Visibility into Data Drives Cost, Quality and Delivery

Reshoring Manufacturing: Visibility into Data Drives Cost, Quality and Delivery As domestic OEMs look to re-shore manufacturing back to the United States, it’s critical to remember how contract manufacturing always has to balance cost, quality, and throughput. With the recent difficulties in delivery of product, companies like Ford are taking the leap at developing their

Digital Twin Fundamentals-Start With Your Goal

Digital Twin Fundamentals-Start With Your Goal Any time you’re thinking of deploying a manufacturing intelligence platform and a full digital twin, the first step is to think of your goal. I watched a webinar recently from the Digital Twin Consortium titled ‘Unlock Transformative Business Outcomes with Digital Twin Fundamentals’. According to the Consortium, part of

Accelerate NPI With Off-the-shelf DVT and SVT Burndowns

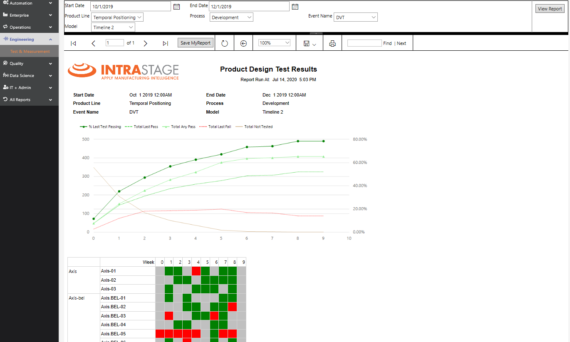

Accelerate Time-To-Market With Off-The-Shelf DVT and SVT Burndown Analytics

In electronics manufacturing, there’s currently a gap between test results traceability to Design Verification Test (DVT) and Software Verification Test (SVT) processes. In addition, program management doesn’t have on-demand visibility into the DVT and SVT progress they need to manage potential schedule slips.

Developing the burndown reports (which show testing progress versus requirements) program management needs takes significant engineering effort and time; that time means that a product is not going to market or customer as quickly as it otherwise could.

An ideal DVT and SVT solution for design engineers and management includes:

- Real-time reporting into progression against requirements,

- Track testing performance over time against requirements for a product in New Product Design (NPI),

- Develop requirements for the product during full manufacturing,

- Dynamically change reporting as requirements change,

- Drill-through to test and parametric measurement performance for characterization,

- Full traceability of coverage by serialized unit and by aggregate,

- Ad-hoc testing against individual items in the master requirements definition,

- Identify areas of failure and areas lacking test coverage,

- The ability to integrate requirements to test results.

- Automate Device History Records, unit history reports, and compliance reports

Customers of BlackBelt Fusion already utilize the above off-she-shelf burndown report to enhance the engineering team’s efficiency and effectiveness while giving improved visibility at the program management level. With this analytic and workflow, the engineering team can concentrate on the testing process instead of taking up valuable time creating the report and analytics needed for visibility and compliance.

Since this workflow leverages our existing datamodel, ETL processes, and solid foundation in complex electronics test. Engineers no longer need to toil in spreadsheets and other analytic platforms; with a web interface that can be automated via subscriptions right to your email inbox, another barrier to time-to-market can be overcome. Another important advantage of having this data into a digital thread in a cohesive manufacturing intelligence platform means that this data is not in a silo that’s inaccessible to the rest of operations and production engineers. By combining this data with the rest of your manufacturing, supplier quality, and repair/rework performance data, you can better identify which factors are affecting failure rates, manufacturing velocity, and quality.

And with that information, you can close the intelligence loop, and improve your processes, product design, and product quality all the more quickly and efficiently. Find out more by contacting us at sales@intrastage.com to get a demonstration of this capability and value.