IntraStage Wins Teradyne Outstanding Service and Support award

IntraStage Wins Teradyne Outstanding Service and Support award

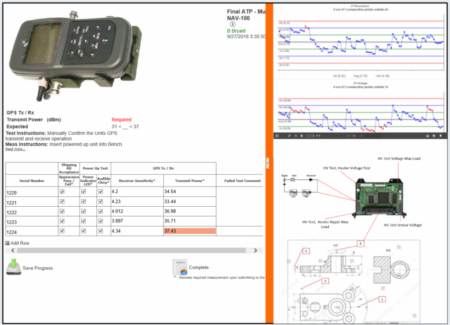

IntraStage is pleased to announce a coveted award from Teradyne to recognize IntraStage’s outstanding service and support.

IntraStage CEO Tom Armes said “We are excited that our long-standing efforts with Teradyne are being recognized for our outstanding support and the willingness to go above and beyond for the Teradyne’s supplier quality team. This kind attention to customer success continues to set the stage for our expanded relationship with the rest of the Teradyne organization. We look forward to continue providing that kind of success and value in 2018 and beyond.”