Faster New Product Introduction

GET THE DEMO

Use our sample data, or useyour data for real insights.

Leverage Your Repair Data to Simulate First Pass Yield

OEMs need to be able to rapidly iterate on their New Product Introduction (NPI) process in order to verify that new design iterations work as expected in the face of part shortage

NPI can be accelerated by having insight into previous models’ manufacturing, repair, and RMA data fused together into a single source of truth.

With this insight, engineers can optimize the design of the new product by estimating failure rates and production issues by isolating known component issues.

Challenge

- Extending lead time amidst increased demand

- Accurate manufacturing forecasting

- Parts shortages driving rapid redesign needs

Solution

- Simulate first pass yield with repair and RMA data

- Tie component failures and issues to cycle time factors

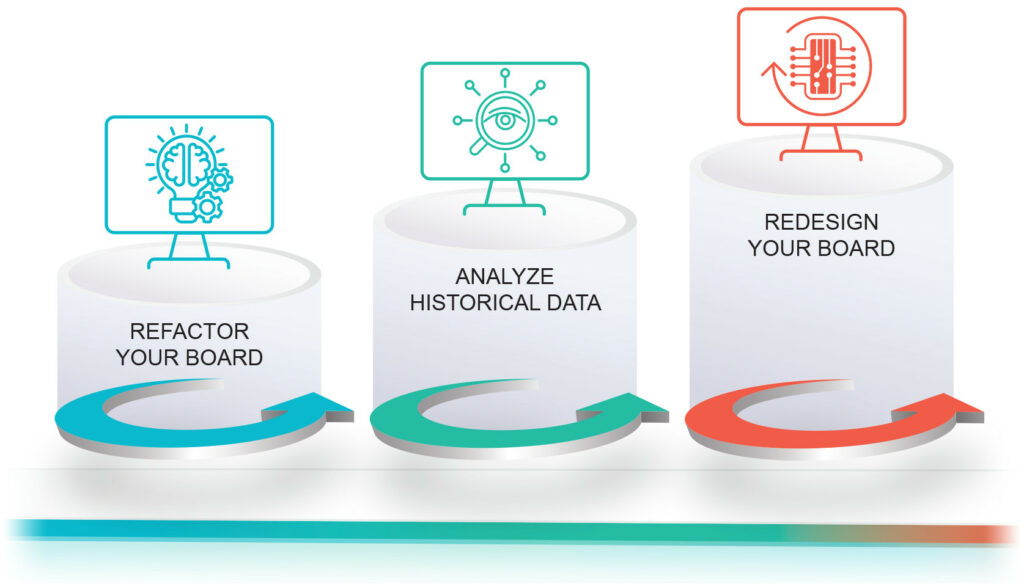

- A Digital Twin to quickly refactor designs

Benefits

- Eliminate customer churn to your competition

- Better throughput and profitability

- Better reliability and faster time to market

By seamlessly integrating all genealogy data from across the product lifecycle, BlackBelt Fusion gives insight into the performance of a complex electronic system down to its constituent parts. Proper use of this information in NPI gives manufacturers a way to understand how known components will perform in a new model, which paves the path towards fast, effective design iterations. Explore this and much more in BlackBelt Fusion, by filling out the Get the Demo form above or contacting us today at:

888.255.2813

sales@intrastage.com