Enterprise Wide Manufacturing Intelligence for Complex Electronics

CARNAC is all about Teradyne's journey to the Factory of the Future

Learn why Teradyne is implementing IntraStage BlackBelt to get faster production time, better quality, and lower costs for their highly complex test instruments

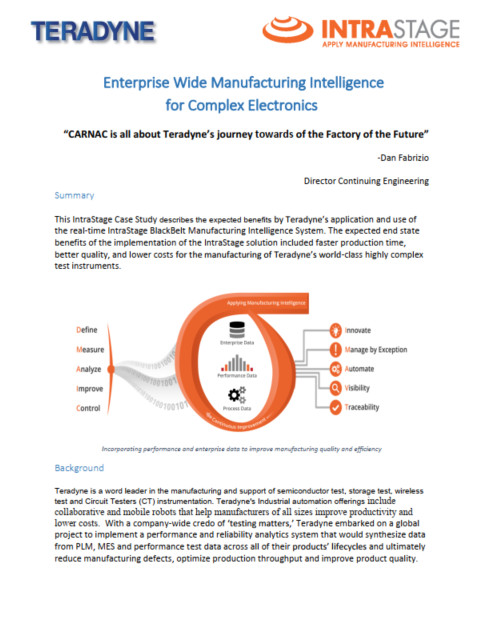

This IntraStage Case Study describes the expected benefits by Teradyne’s application and use of the real-time IntraStage BlackBelt Manufacturing Intelligence System. The expected end state benefits of the implementation of the IntraStage solution included faster production time, better quality, and lower costs for the manufacturing of Teradyne’s world-class highly complex test instruments.

Download this whitepaper to learn how Teradyne normalized datasets from:

- Contract manufacturing data, which included assembly level information for serialized LLAs and HLAs

- PLM data from Siemens Teamcenter (including BOM, Part, and AML)

- MES process data, including repair and rework data from the contract manufacturer

- A subset of parametric test, which was stored in a separate structured data warehouse and summary data extracted into Carnac containing terabytes of performance information from individual boards. This parametric data was extracted to correlate failing parametric measurements with rework data.