- Web-access to all tester records and analytics

- UUT History/Event Report

- Raw data support, including waveforms

- Complete Serial Number History Report

- Characterize and Correlate

- Statistical Process Control (SPC)

- Failure Paretos

- Station Performance and optimization

- Test Process Performance

- First-Pass, Last-Pass, Throughput Yield

- Retest/Rework

- Drilldown from Yield or SPC to unit performance

- Web-based graphs and charts

- Traceability

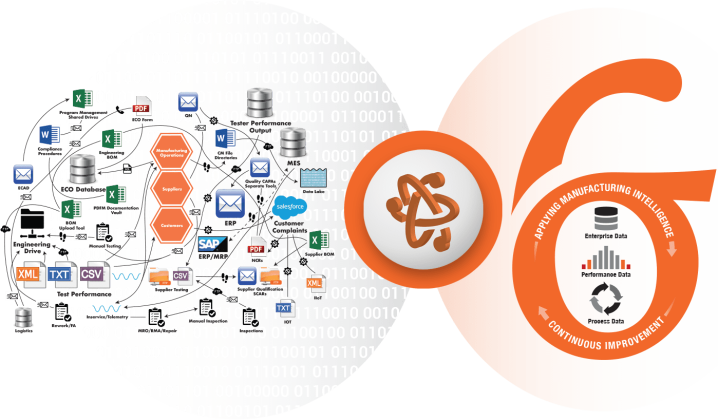

Manufacturing Intelligence means having the off-the-shelf analytics and documentation to deploy and support advanced test engineering features:

- Gage R&R on-demand

- Realtime SPC and WECO

- Hidden Factory

- Other DB integration

- Enterprise integration

- Emerging standard and best practices

- Workflows

- Spec phase/requirements

- Subscriptions

- The Power of Attributes and Metadata

- Applying Machine Learning and A.I.

- Strategy for Very Large Datasets

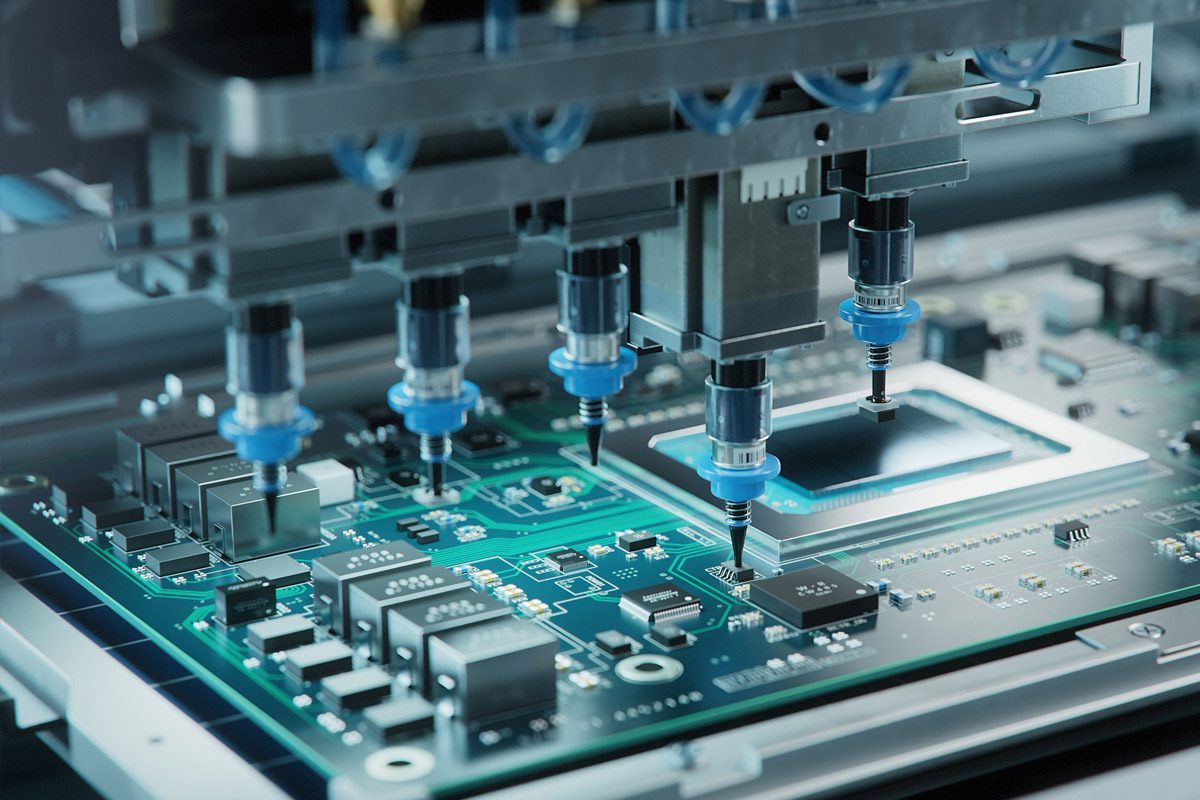

Building the Digital Thread for Electronics Manufacturer requires the ability to seamlessly incorporate new and upcoming sources of manufacturing data, enterprise attributes, and other silo’d data sources.

- What to consider when implementing a new test format

- Extensibility

- Compatibility

- Future Proof

- Raw Data support

- Customized Formats

- Binary, text, images, PDF, other

- (PDF download) Application of ATML Test Results and IntraStage to facilitate Intelligent Data Analysis

- (PDF download) How To Use Test Data to Better Manage ATEs

Validated data connectors, converters, and normalization for fidelity of process and data for quicker, more successful deployments.

For more than fifteen years IntraStage has been working with hundreds of different data formats. Learn more about how we have accessed and transformed using many different technologies into our standard data format.

Success with a Manufacturing Intelligence platform requires a firm understanding of a company’s current manufacturing environment, digital readiness, and roadmap to the factory of the future.

- Customization and Integration use case

- Integration of manufacturing parametrics with existing PLM, ERP, and MES

- ETL process for new datasets

- Features of a complex electronics data warehouse

- (PDF Download): Digitize Your Paper-Based Test Data to Generate New Insights

- What Does SPC Mean To You and Your Organization?

- Achieving Success With a Phased Approach

Lack of visibility into failure reasons and yield issues. Lack of tracking process anomalies which impact the overall manufacturing throughput.

Lack of characterization on performance issues.

No way to be proactive on line-stopping issues and problems. Ability to monitor critical KPI’s in real-time with Alerting and enterprise level visibility.

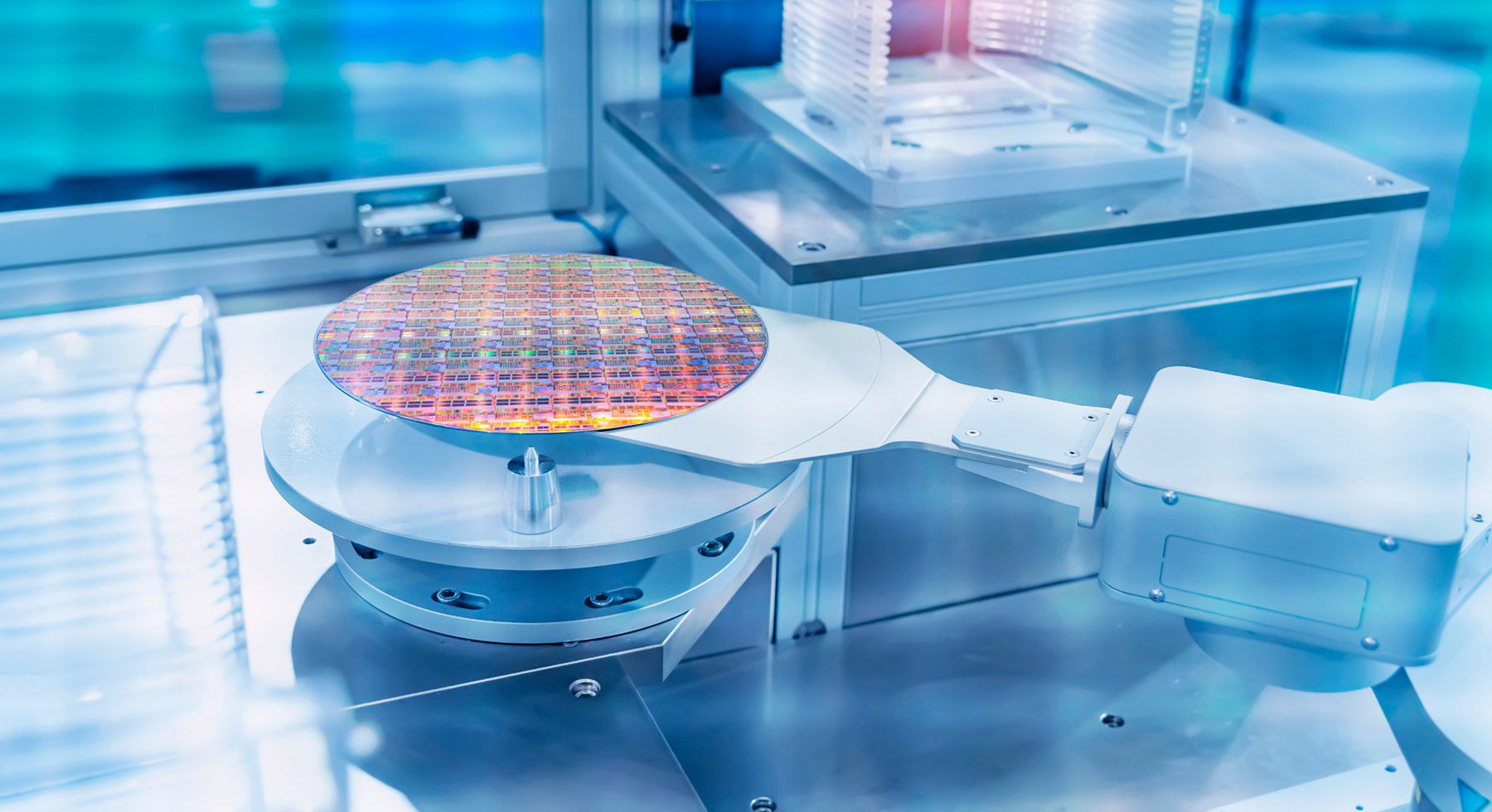

Multiple product lines with data from across the product lifecycle, including supplier subcomponents, contract-manufactured lower-level assemblies (LLAs), and higher-level assemblies (HLAs).

Need for correlation and tracking of performance, rework and reassembly of LLAs into and with HLAs with full product genealogy.

Need to integrate Manufacturing data with enterprise systems (Flexflow-MES, Team Center – PLM, Agile PLM, Spider- QMS, BOM and Oracle – ERP/AVL ).

BlackBelt Analyze allows small manufacturing businesses to quickly process and combine data from multiple sources into a common silo for test data management analytics.

IntraStage designs and develops software for SMBs, mid level and enterprise level complex electronics manufacturers. We serve the following industries, aerospace, medical device manufacturers and consumer electronics.