Ship your product with full traceability of process and test performance.

Blackbelt is a complete compliance verification system that ensures error-proof products are ready to ship for electronic device manufacturers. Blackbelt is designed for Operations management who need a low-cost, efficient, easy-to-use solution for product and process verification.

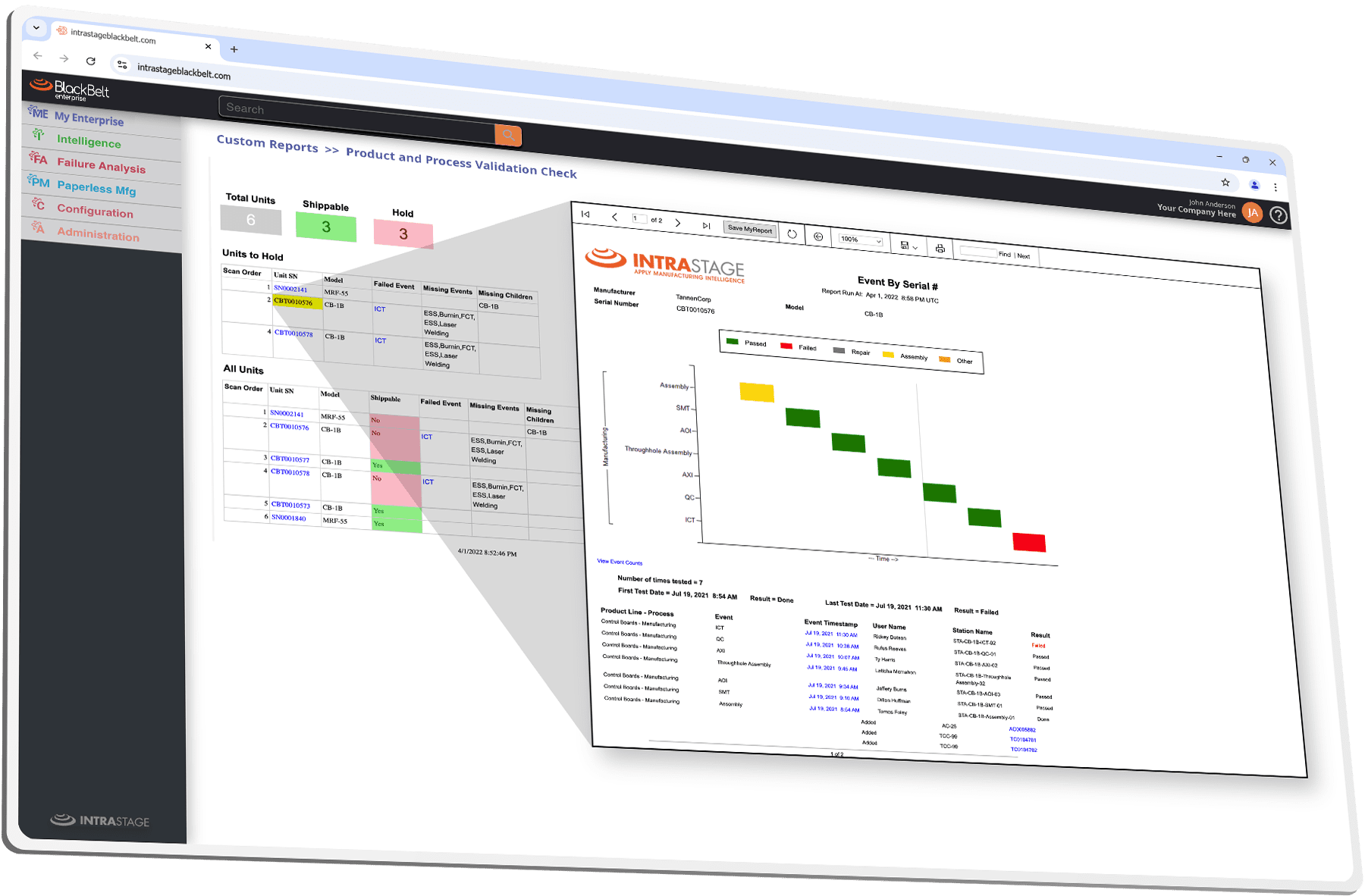

Unlike paper-based processes or spreadsheets or bloated MES/ERP implementations, BlackBelt delivers a real-time single source of truth insight to the shop floor. See any products’ manufacturing status along with all related parts in its genealogy. Verify that your supplier parts and components are following the manufacturing test process they should.

Validate that your assembled products pass each quality and test step in their process.

Features:

- Traceability up and down genealogy

- Low cost simple deployments

- Digital forms for inspection and assembly

- Electronic Device History Record (eDHR)

- Standalone and upgradable module

Values:

- Easier regulatory and contractual compliance

- Verify serialized components have followed your Process Definitions

- Self-serve to upload or input data into your new system in hours

- Realize value quickly without a need for long-term financial commitments

- Future-proof and sets the foundation for Enterprise and the Digital Twin

LEONARDO needed to identify and minimize manufacturing/repair touch time as well as the ability to investigate yield and performance issues at multiple sites with Secure and Secret deployments.

They required the ability to analyze disparate data from complex test systems and normalize analysis data from ATML, NI TestStand, LabVIEW TDMS, PDF and text, CSV and Excel formats.

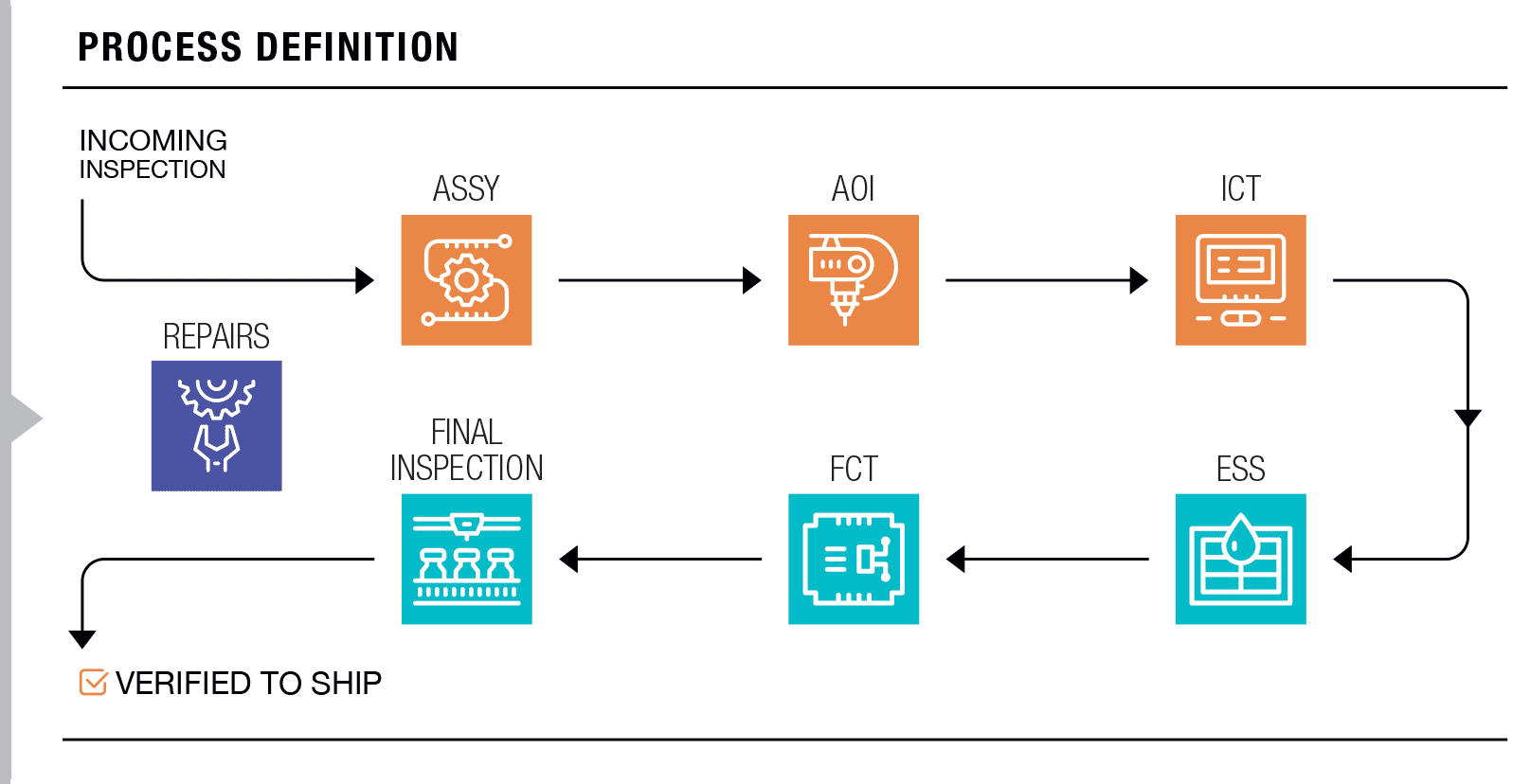

Highly complex products with tight safety and reliability metrics. Need to analyze production data to quickly identify issues affecting yield and performance. Data aggregation from AOI,AXI,ICT,FCT, ESS, Failures, Rework and ATP performance test.

Apply Statistical Process Control ( SPC) across a wide number of process variables such as CpK.

“IntraStage core technologies has enabled the visibility needed to achieve a 90% reduction of our yield issues. This helped ultimately reduce our Cost of Goods Sold by £ 500,000 / year via achieving target improvements in Rolled Throughput Yield.”