Fuse the digital thread and the digital twin to give you the full picture of product performance. Bridge enterprise silos with every stage of your products’ lifecycle.

Parametrics are the lifeblood of your product’s quality, and attributes are its character. From NPI to Supplier Quality to Manufacturing to RMA/MRO, you can use IntraStage to apply manufacturing intelligence to accelerate business decisions.

Automate root-cause workflows and analysis across your enterprise systems. Fuse your product performance data with your enterprise data attributes from PLM, ERP, and MES to provide click-through drill-down capabilities from a single-source of truth.

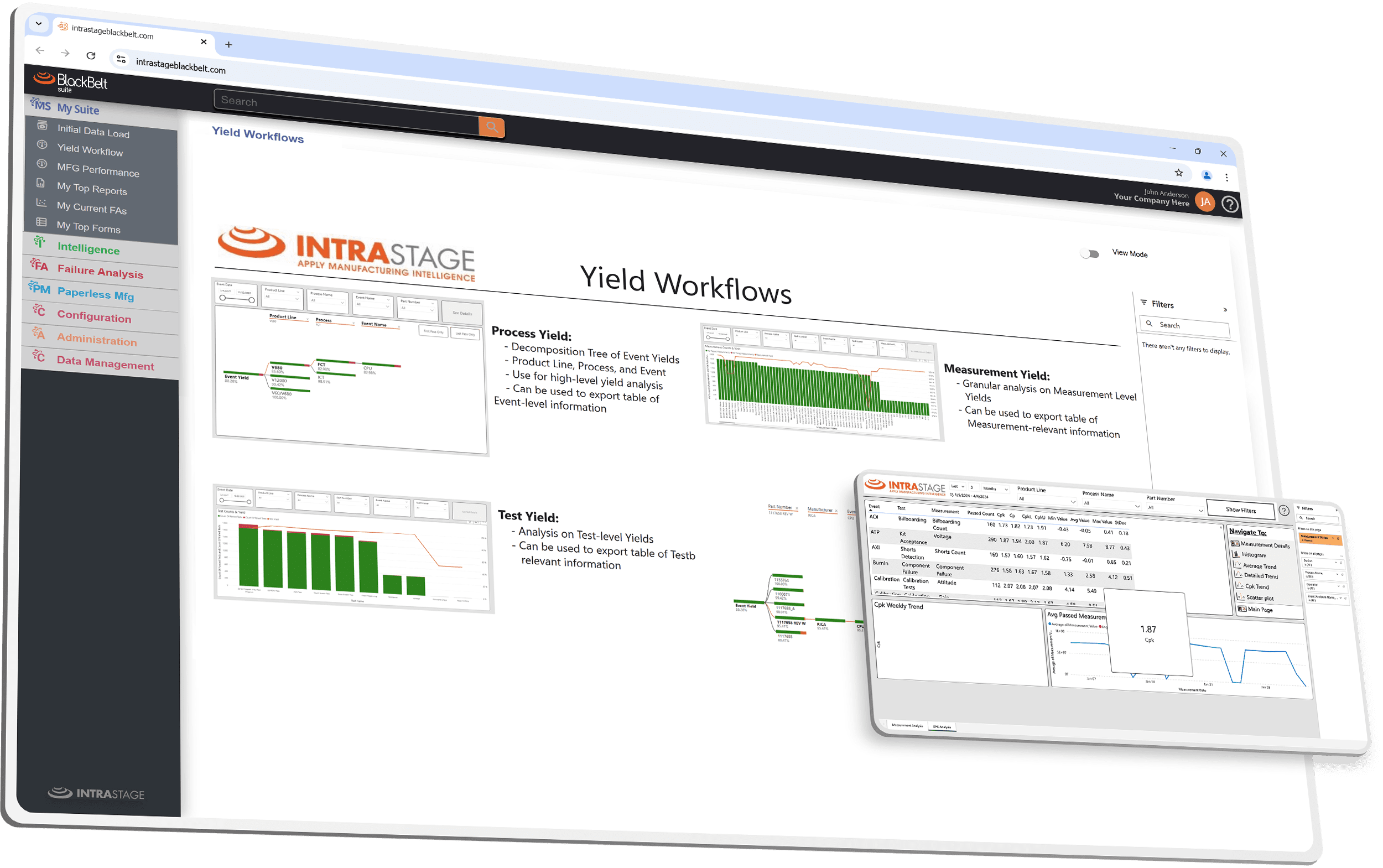

Workflows Ready for Each Step of Your Digital Transformation

Automate root-cause workflows and analysis across your enterprise systems. Fuse your product performance data with your enterprise data attributes from PLM, ERP, and MES to provide click-through drill-down capabilities from a single-source of truth.

Workflows Ready for Each Step of Your Digital Transformation

- Automate Visibility of KPIs

- Manage by Exception with Smart Alerts

- Control your process stability with real time SPC including Xbar-R and WECO

- Integrated Root-Cause by outlier characterization

- Automate prediction using weighted probability and clustering techniques

- Link relevant enterprise data systems to gain visibility across your products’ genealogy from component to module to assembly.

- Aggregate performance metrics across your enterprise provide actionable insights

Integrate your NPI, R&D and Engineering data with your Manufacturing test data to speed the insights that drive product development.

Associate and Predict

Integrate your NPI, R&D and Engineering data with your Manufacturing test data to speed the insights that drive product development.

Associate and Predict

- Collect Data and Analyze for Qualification, Verification and Characterization

- Correlate product performance across each step in new product introduction

- Quickly compare performance results from previous designs across the products’ lifecycle history

- Feed your favorite software analysis tools with wide open data access

- Maximize product quality by applying correlated characteristics of performance and design failures to prescribe resolutions

- Maximize process throughput by automated identification of bottlenecks

Reach beyond compliance and maximize service life with component reliability analytics and failure analysis workflows.

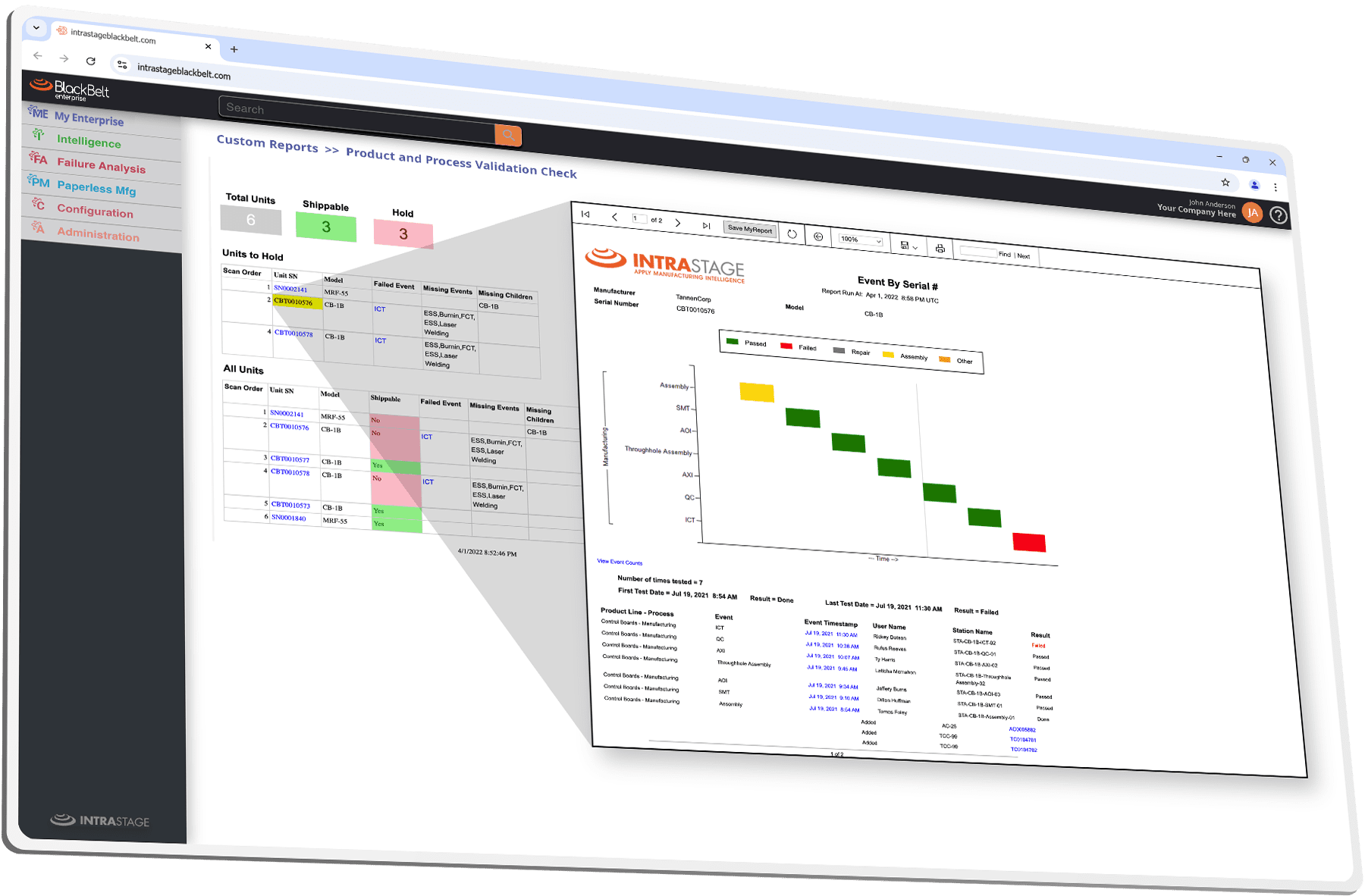

Smart Workflows

Reach beyond compliance and maximize service life with component reliability analytics and failure analysis workflows.

Smart Workflows

- Capture all attributes of diagnostics and root cause with tailored forms with rapid time to value

- Integrated, flexible approvals and signing authority

- Speed your MRO process with diagnostic reporting

- Connect with existing Enterprise Non-conformance systems (SAP, Oracle, MRP, ERP, PLM)

- Connect with your CRM systems to automate the initiation of return analysis and provide better customer communication and satisfaction

- Reliability analytics in a single solution (MTTF, FIT Rates, etc)

- Track unit life-cycle performance

- Reduce service cycles with normalization and modeling of data for clustering and advanced analytics

The voice of your customer is in your returns. Are you listening?

The voice of your customer is in your returns. Are you listening?

Capture and analyze customer return data to better understand where processes and products need to evolve to improve product quality.

Product Quality Insight

- Quickly understand why your customers are returning your products, and know how to resolve the issue: Characterize RMAs by Defect/Model/Return Rate/Customer/Supplier/Contract Manufacturer

- Use enterprise-level analytics that drive better product quality: use drill-down enterprise analytics like Mean Time Between Control Failures (MTBCF) Mean Time Between Failures (MTBF) and Mean Time To Repair/Return (MTTR)

RMA Process Quality Control

- Fully track RMAs from genesis to completion, and have the confidence that your RMA processes are compliant and cohesive: integrate with CRM and ERP using the IntraStage API

- Gain insight into efficiency and productivity metrics like Warranty Analytics and Cost of Repair/Labor Analytics

As a high-volume manufacturer with a dedication to higher quality and lower customer returns, Calix needed a way to track and control the RMA process.

RMA data for each customer was tied directly to customer satisfaction and Calix profitability.

Needed to replace two existing, incompletely integrated RMA/FRACAS commercial, off the shelf software system and processes in a very tight (less than one month) timeframe.

General Atomics needed to analyze gigabytes of test data from ATEs producing LabVIEW and TestStand data outputs on the manufacturing floor to identify issues that affect manufacturing efficiency and product quality.

They also wanted to be able to digitize paper-based manufacturing data capture to facilitate data analysis and improve process integrity.

IntraStage was also tasked with enabling the processing of data from multiple manufacturing lines and systems.