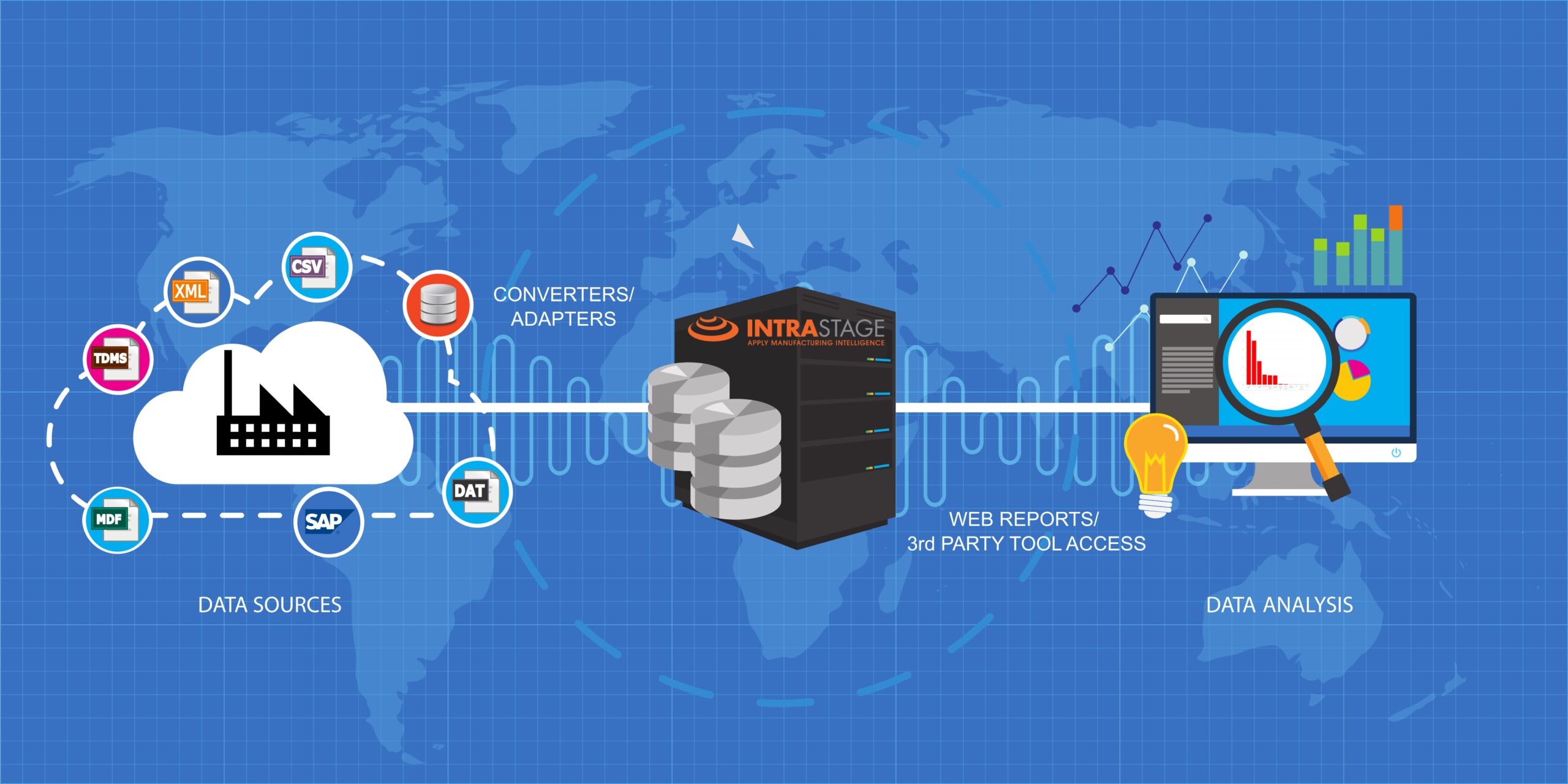

Using our prebuilt, off-the-shelf standard adapters, custom converters, or custom adapters, incorporate performance and process data from across your enterprise, without having to disrupt your manufacturing line or change the outputs or your manufacturing process.

- Standardized IEEE ATML, NI TestStand and LabVIEW (TDMS) adapters

- Leverage your test code to output our standard CSV output

- Broad ICT and FCT reference library

- Off-the shelf adapters and converters for common data formats

- Low-code CSV mapping technology

- Training and documentation for in-house converter development

- Advanced data load logic (reference files, custom tables, duplicate event handling, exception handling)

- Conforming checks

- Rich error reporting & notifications

- Data load tracking and traceability

- Duplicate detection and rejection

- Data monitoring subscriptions and alerts

- Clean and normalized transformation/automation

Once that data is normalized into the IntraStage BlackBelty system, give your engineers full lifecycle traceability on your Products. Drilldown to failure, SPC, or yield issues on your final product, sub-assemblies, or even individual components via stock web reports.

Or, grant secure read-only access to your single source of manufacturing truth to your engineers and analysts via 3rd party tools (like Minitab, DIAdem, Excel, PowerBI, and other standard analysis applications).

Gather the parametric and process details that drive quality. From FCT, ICT, Burn-in, Calibration, Paperless Forms, Waveforms, and other types of data critical to complex electronics manufacturing, normalize your product performance details in the same data warehouse. Give your users from NPI, R&D, Quality, Operations, Manufacturing, and Supplier Quality the same single source of truth on quality and yield.

Validated data connectors, converters, and normalization for fidelity of process and data for quicker, more successful deployments.

For more than fifteen years IntraStage has been working with hundreds of different data formats. Learn more about how we have accessed and transformed using many different technologies into our standard data format.

Let us know. We can help your team identify measurements, characteristics, and the digital thread that connects your custom formats into the Factory of the Future.

LEONARDO needed to identify and minimize manufacturing/repair touch time as well as the ability to investigate yield and performance issues at multiple sites with Secure and Secret deployments.

They required the ability to analyze disparate data from complex test systems and normalize analysis data from ATML, NI TestStand, LabVIEW TDMS, PDF and text, CSV and Excel formats.

Highly complex products with tight safety and reliability metrics. Need to analyze production data to quickly identify issues affecting yield and performance. Data aggregation from AOI,AXI,ICT,FCT, ESS, Failures, Rework and ATP performance test.

Apply Statistical Process Control ( SPC) across a wide number of process variables such as CpK.

“IntraStage core technologies has enabled the visibility needed to achieve a 90% reduction of our yield issues. This helped ultimately reduce our Cost of Goods Sold by £ 500,000 / year via achieving target improvements in Rolled Throughput Yield.”