With intuitive workflows, BlackBelt Enterprise helps manufacturers validate both the form, assembly, and integrity of parts and process. Here are some of the key benefits:

- Improve quality and reliability by capturing the full product lifecycle

- Eliminate technical debt of homegrown solution with COTS solution

- Bridge the chasm between IT and manufacturing data

- Instantly certify product quality and process

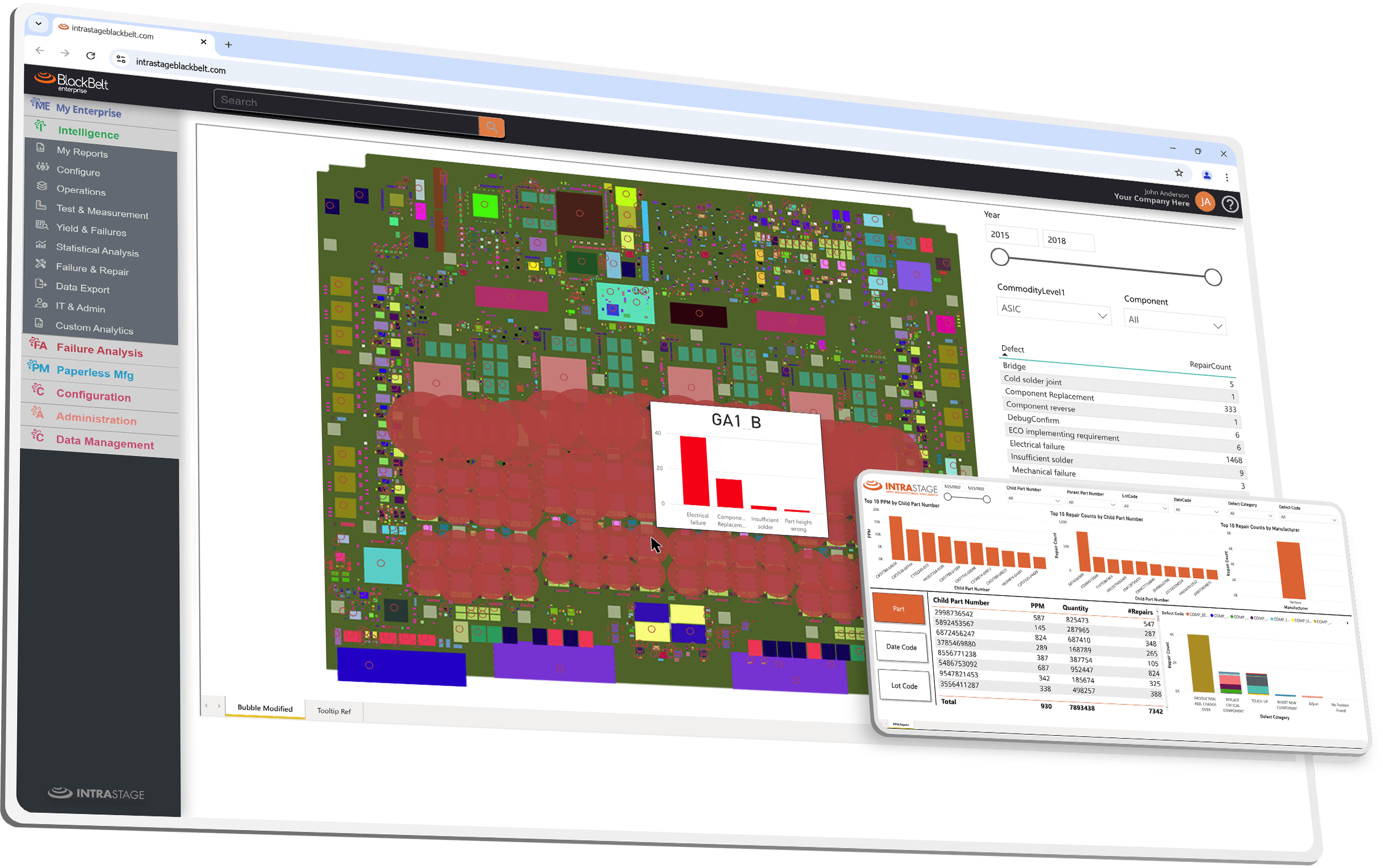

Analyze and report on highly complex products with tight safety and reliability metrics. Need to analyze production data to quickly identify issues affecting yield and performance.

Data aggregation from AOI,AXI,ICT,FCT, ESS, Failures, Rework and ATP performance test. Apply Statistical Process Control ( SPC) across a wide number of process variables such as CpK.

- All Features in BlackBelt Analyze and BlackBelt Suite

- 3rd Party Access to system for data extraction

- Failure Analysis Module(Included)

- Unlimited User Defined Roles

- ERP/MRP, CRM, MES, PLM integration available

- Genealogy (Parent/Child relationships for As-Built)

- Assembly/Disassembly Forms

- Multiple Projects Supported (Data Segregation)

- On-Site Deployment Supported (Minimum software and hardware requirements)

- Customer Azure Tenant Installation Supported

- Hybrid Cloud Supported

Streamline your manufacturing productivity, reduce engineering cycle-time and improve product quality with lighting-fast insights that drive business decision in real-time.

Experience the power of next generation in-memory analytical processing that supports full product life cycle intelligence with a rich set of advanced manufacturing analytics.